Multiple Waveforms of GCC LaserPro S290LS | Laser Engraving, Vinyl Cutter, UV Printer - GCC

Knowledge Base

| A waveform is a pulse with a specific shape, pulse energy and duration. The benefits of a waveform are that it allows customers to adjust pulse conditions to optimize marking, micromachining and applications. Users enjoy flexible control over pulse duration and peak power through the use of predefined waveforms. Each waveform is optimized for pulse energy and peak power at a given pulse duration and frequency. These waveforms work for any power demands and frequencies giving users a great scope of pulse characteristic optimization for specific applications. |

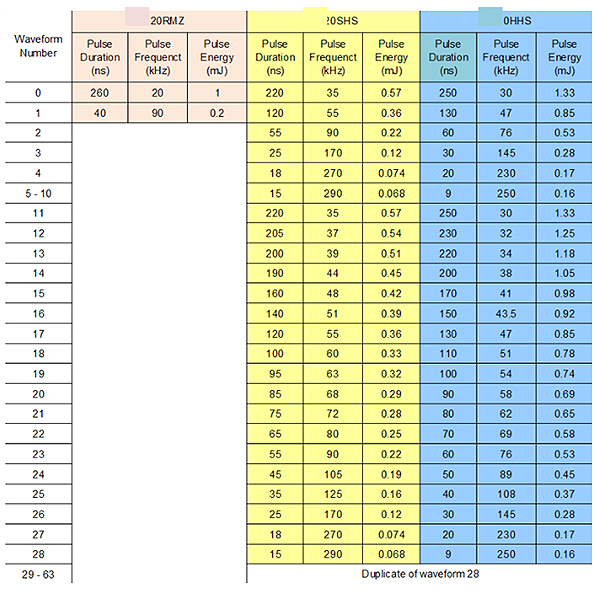

| Below is a table of the corresponding waveforms for different S290LS wattages: |

|

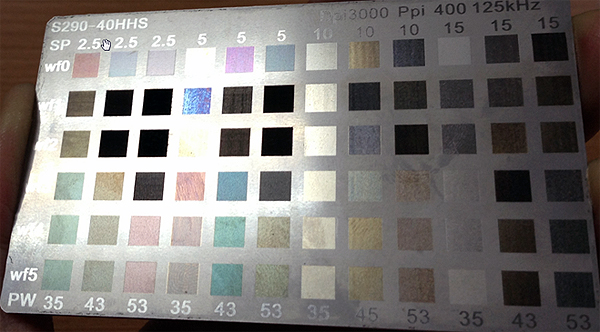

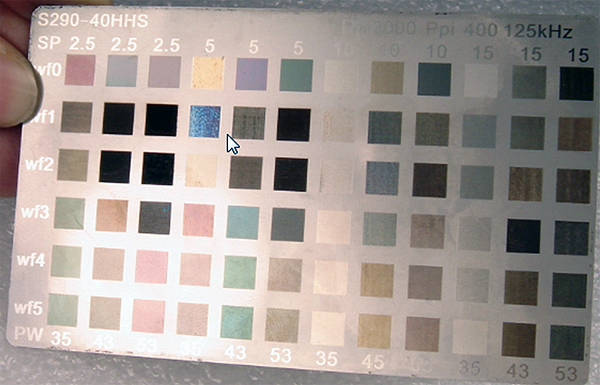

| One of the benefits of waveforms is that color marking can be achieved on metal materials. In the picture below, the S290LS 40HHS model is utilized to process matt 304 stainless steel. |

|

|

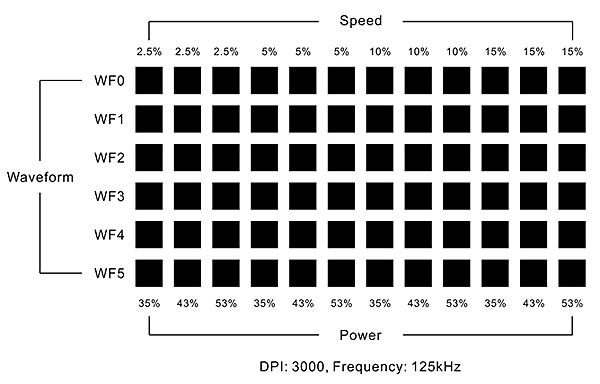

| The first step of this process is to design a matrix with fixed speed/power range and frequency, then set multiple waveforms as the key parameter; different colors will be marked by laser once this is done. |

| Here is the suggested parameter setting for the 40HHS model:

|

| Next you will have to select the preferred color, and repeat the corresponding parameters to color your graphic design. This process will greatly save your time compared to traditional complicated parameter experiment steps. |

|

| TIPS:

|

| NOTE:

|