2021 Things You Should Know Before Buying a Laser Engraving Machine

What is laser engraving machine?

LASER is the acronym for Light Amplification by Stimulated Emission of Radiation. Laser engraving is the process of subtractive manufacturing to engrave material surface using a laser beam. It is a non-contact process, as the high heat and energy of laser melts and vaporizes the area where you are aiming the laser beam at.

Finally, it leaves a permanent mark on the surface, usually used to create an image of the material. With graphic software and parameter, laser engraving can produce amazing effects, such as photo or 3D engraving.

How does a laser engraving machine work?

A CO2 laser works by electrically stimulating the molecules of a carbon dioxide gas mixture. When focused through a lens, this invisible intensive beam can vaporize many materials. Depending on the speed and intensity of the beam, CO2 laser can be used to engrave a wide variety of materials.

For customers, it is fairly easy to operate the laser system for engraving and cutting, similar to the way your paper printer prints. You can install most kinds of graphics software in the Windows system, such as CorelDraw, to design the graph you need. Set the page size to the same as the plaque, trophy, or other objects you will be engraving, and print it to the laser. With adjustable speed settings from 0.1% to 100%, power settings from 1% to 100%, and dpi settings of up to 1000, the engraver will print with as much depth and detail as you need.

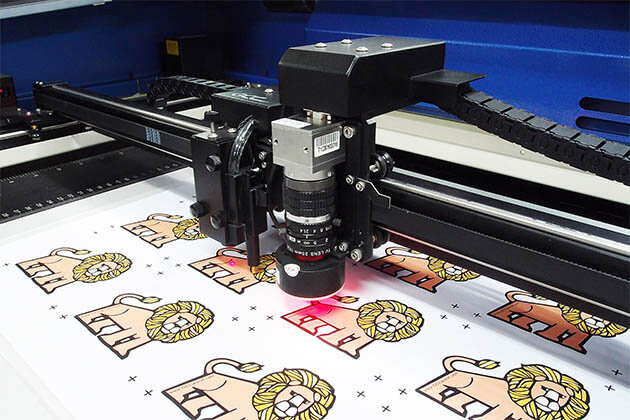

There are two ways how a laser engraver works; one is raster, and the other is vector. Raster is like a high clarity lattice printing, where the laser head scans left to right, engraving a series of dots one line at a time, then moves back and forth to carve as many lines as needed to make up a full-page picture or characters. Different from raster, vector proceeds on the outline of the characters. We usually use this model for cutting materials, like woods, acrylic, and paper, or marking on the surface of them.

What is a laser engraving machine used for?

The versatility of laser system means that it works on many materials, including wood, acrylic, plastics, stone, metals, etc. In particular, it is a great tool to add numbers, logos, images, and serial numbers to parts. Laser engraving is today a technology commonly used for producing promotional products like pens, signs, and displays, which makes laser engraving suitable for a variety of industries, such as signage and advertising, personalization and identification, gifts and promotions, post-press, apparel, and electronics industries.

One of the most noticeable applications is customization which is popular nowadays, like a wedding ring with a name on it. It is more effective than traditional engraving for small objects.

In the apparel industry, it is most common to use laser machines to directly engrave customized patterns on materials. It is also applied to heat transfer vinyl, especially thick or stretchable materials. The laser engravers cut quickly and accurately, thus replacing the traditional cutting method.

Find out more on our Applications.

How much does a laser engraving machine cost?

Laser engraving machines are widely used in various engraving and cutting jobs because of the smooth cutting surface, fast cutting speed and high precision, especially in industries that have higher standards and requirements for cutting speed and accuracy. However, when buying a laser machine, people are likely to be confused as to which laser engraving machine to choose and what the price of the machine is.

It is difficult to give a simple answer as it depends on your needs or what kind of work you want to accomplish? Before starting all projects, you first need to consider the material you want to process and its production volume, and then you determine the specs you desire for the machine, such as the type of laser, wattage, and working area size. Different types of laser engraving machines have different functions and applications. Generally, the greater the wattage and work surface, the higher the cost.

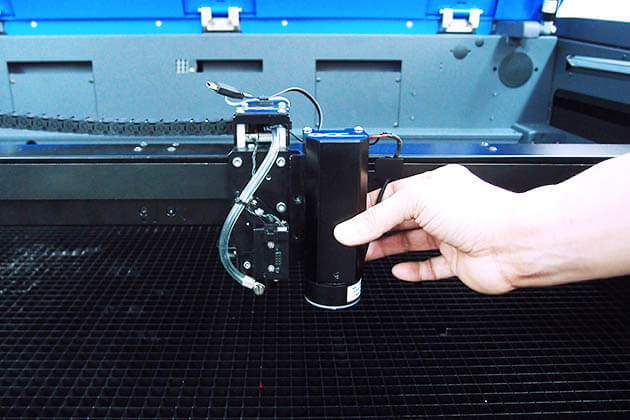

Another thing to consider when buying a laser engraver is the cost of maintenance. The amount of cleaning required for machine maintenance depends on the materials used. Sometimes mirrors or lenses need to be finely cleaned, and the machine may also need to be realigned. Regular maintenance and cleaning help avoid consuming too much time and interrupting the company's production line. There is also the after-sales service, which may incur labor and parts costs when necessary.

With all of these having been taken into account, you just need to contact us, and we will help you choose the right model that suits your needs.

Why is a laser engraving machine so expensive?

The price of a laser engraving machine varies widely from one model to the next. There are some low-cost and self-assembled units available at US$100-300, but the limited efficiency and laser power can only handle paper or the surface of wood and plastic. However, there are some high-quality units that cost dozens of times or even more. This massive difference in equipment cost is reflected by the significant difference in machine quality, functionality, and performance.

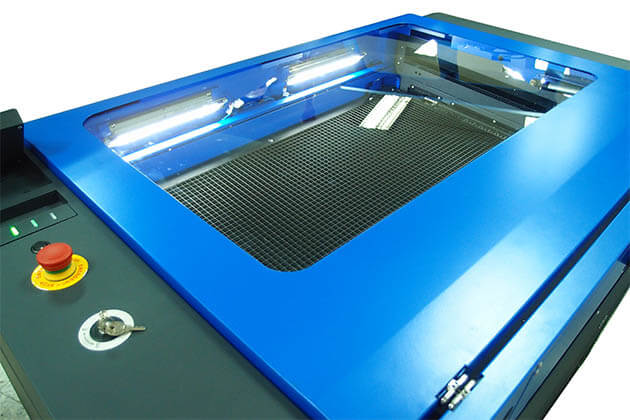

High-quality laser engravers typically consist of durable components that do not break down easily and powerful lasers that cut through a variety of materials precisely and quickly. High-quality laser engravers use software that is compatible with many programs, making them highly versatile. Finally, it has a comprehensive warranty and service package that protects you from equipment malfunctions and breakdowns (usually lower-cost laser engravers are not provided with warranty and service and eventually given up).

While it may be tempting to buy the most inexpensive laser engraving machine so you can spend the least money on your latest beloved project, perhaps a more expensive machine is a wise investment for you in the long run. Investing more money into a higher-quality unit means longer service life and smaller maintenance costs, both of which will lead to lower overall equipment costs.

Regarding the high-quality laser engravers, you just need to contact us, and we will help you choose the right model that suits your needs.