Twill Cutting with X-Series | Laser Engraving, Vinyl Cutter, UV Printer - GCC

-

X252 Laser Cutter

X252 Laser Cutter -

🆕E200 Desktop Laser Engraver

🆕E200 Desktop Laser Engraver -

X380 Laser Cutter

X380 Laser Cutter -

Venus II Desktop Laser Engraver

Venus II Desktop Laser Engraver -

X500III Laser Cutter

X500III Laser Cutter -

C180II Desktop Laser Engraver

C180II Desktop Laser Engraver -

Mercury III Laser Engraver

Mercury III Laser Engraver -

T500 Laser Cutter

T500 Laser Cutter -

Spirit Laser Engraver

Spirit Laser Engraver -

Spirit LS Laser Engraver

Spirit LS Laser Engraver -

MG380Hybrid Laser Engraver

MG380Hybrid Laser Engraver -

Spirit GLS Laser Engraver

Spirit GLS Laser Engraver -

Spirit GLS Hybrid Laser Engraver

Spirit GLS Hybrid Laser Engraver -

S400 Laser Engraver

S400 Laser Engraver

Twill is a type of fabric material that is very suitable for logos due to its stiffness and multi-layer lamination.

Traditional Twill logo has a quite complicated manufacturing process. First, the Twill needs to be cut into multiple pieces of layers and laminate back together. Not only is it inconvenient to align, laminating is also very time and cost consuming. Thanks to technology, the use of lasers in multi-layer appliqué for Twill logo is definitely your best solution.

This month, GCC LaserPro Application Lab will demonstrate the applications of multi-layer appliqué of Twill. You can first laminate the layers of Twill together, and use the professional GCC LaserProX-Series for cutting. GCC LaserPro driver offers multiple sets of parameters settings, allowing you to adjust cutting parameters for different layers of Twill. Adjustable PPI also allows the laser output to be more stable, so the Twill can be cut in one process, eliminating further alignment and laminating work after cutting. All you need to do is strip the unwanted parts off and it can be directly heat pressed on clothes for easy mass production. Now, let’s take a look at GCC LaserPro Application Lab demonstrations!

Materials:

- Twill

Procedures:

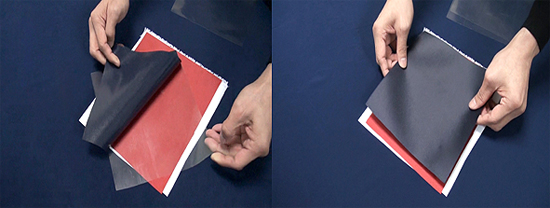

Step 1. Laminate 3 layers of Twill together

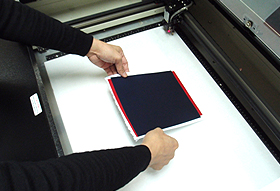

Step 2. Placed the laminated Twill on the working table

Step 3. Press the auto-focus button for auto-focus

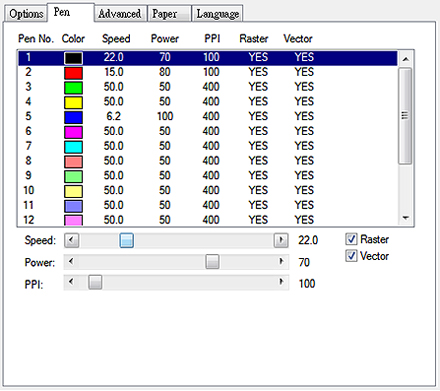

Step 4. Use different colors of pen at the Driver’s end to set cutting parameters for different layers of Twill

Step 5. Press Start and begin processing

Step 6. Place the twill on the desired ideas that need to be printed and place it firmly by doing Heat Press.

Step 7. Sample Complete

Suggested parameters:

| X252 80W | ||||

| 1 layer cutting | ||||

| Speed | Power | DPI | PPI | Other |

| 22 % | 70 % | 1000 | 100 | Manual color fill |

| 2 layer cutting | ||||

| 15 % | 80 % | 1000 | 100 | Manual color fill |

| 3 layer cutting | ||||

| 10 % | 100 % | 1000 | 100 | Manual color fill |

*The parameters are for suggestions only and should be moderately adjusted accordingly.

Tips:

- Before cutting, please make sure the Twill is flat to avoid image being out of focus and result in defective cutting.

- Too many layers of Twill laminated will lead to the bottom material being out of focus. It is recommended to laminate a maximum of 4 layers.

- Reduce PPI can avoid the bottom layer of Twill to be cut off directly. Recommended setting for PPI is 100.