EPE Cutting | Laser Engraving, Vinyl Cutter, UV Printer - GCC

-

X252 Laser Cutter

X252 Laser Cutter -

🆕E200 Desktop Laser Engraver

🆕E200 Desktop Laser Engraver -

X380 Laser Cutter

X380 Laser Cutter -

Venus II Desktop Laser Engraver

Venus II Desktop Laser Engraver -

X500III Laser Cutter

X500III Laser Cutter -

C180II Desktop Laser Engraver

C180II Desktop Laser Engraver -

Mercury III Laser Engraver

Mercury III Laser Engraver -

T500 Laser Cutter

T500 Laser Cutter -

Spirit Laser Engraver

Spirit Laser Engraver -

Spirit LS Laser Engraver

Spirit LS Laser Engraver -

Spirit GLS Laser Engraver

Spirit GLS Laser Engraver -

Spirit GLS Hybrid Laser Engraver

Spirit GLS Hybrid Laser Engraver -

S400 Laser Engraver

S400 Laser Engraver

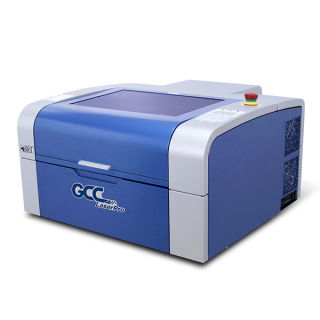

The GCC LaserPro Application Lab has previously introduced various packaging projects. Laser is an efficient and practical tool for processing both outer and inner packages. This month, the GCC LaserPro Application Lab characterizes another packaging project by using EPE (Expanded Polyethylene), a material with exceptional elasticity and impact strength that is widely used in protective packaging.

Traditionally, EPE is cut through casting molds tailored to the specific shape and size requests. It is a huge bill to face for small number production. Laser cutting systems eliminate the worries as all you need is send designed images to the system to allow mass production, saving the cost of casting molds. Here is the LaserPro demonstration on EPE:

Procedures:

Step 1. Place the EPE board on the honeycomb table.

Step 2. Press "Autofocus" to automatically set the focal distance.

Step 3. Press "Start" to begin processing.

Step 4. Sample is complete.

Suggested parameters:

| Spirit GLS 100W | ||||

| Speed | Power | DPI | PPI | Other |

| 3 % | 100 % | 500 | 400 | Air Assist |

*The parameters are for suggestions only and should be moderately adjusted accordingly.

Tips:

- Before you start the job, please make sure the EPE board is completely flat and even to ensure cutting quality.

- Please keep the air assist system on to improve cutting quality.